Our company production of glass fiber reinforced plastic straight ladder, protect the ladder, platform ladders, etc., we can produce products with different styles, different sizes, different colors, can also provide customized service.

Application

This product can be used in the following areas: chemical industry, paper industry, power plants, sewage treatment plant, food processing plants, smelters, ore Mountain, saltworks, nuclear power plants, storage battery factory, etc. Can be used as a pedestrian walkway, bridge plate, industrial floor, operation platform, trench cover plate, tray, guardrail, fence, shelves, isolation belt, green corridors, Floor mark time, etc.

FRP Pultrusion production process is a continuous production process to produce fiber-reinforced polymer profiles of any length and constant section. Reinforcement fibers may be roving, continuous mat, woven roving, carbon or others. The fibers are impregnated with a polymer matrix (resin, minerals, pigments, additives) and passed through a pre-forming station that produces the stratification necessary to give the profile the desired properties. After the pre-forming step, the resin-impregnated fibers are pulled through a heated die to polymerize the resin.

Main features:

· Light weight and high strength

· Good looking, anti-corrosion

· Free maintenance, fire retardant

· Excellent insulation, magnetic permeability

· Easy and quickly installation or cut

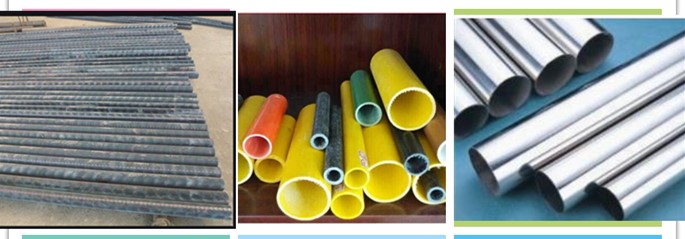

| Performance | Iron | FRP profile | Steel |

| cost | Low | medium | High |

| material | Metal | fiber glass & polyester | Metal |

| Weight | Heavy | light weight | Heavy |

| strength | Low | high strength | High strength |

| Corrosion resistance | ordinary | excellent | excellent |

| severce life | 5-10 years | 10-20years | 15-20 years |

| Media performance | Conductive and thermal conduction | Insulation | Conductive and thermal conduction |

| Rusty | Easy to rust | Non-rusty | Easy to rust when nickel content is low |

| Recycle | YES | NO | YES |

Our company was founded in 1993, introduced the world's most advanced FRP full-automatic pultrusion production equipment and inspection & testing equipment for products and materials from US . All staffs are trained by American experts. Through their hard work and research, they not only master the advanced technology of foreign countries, but also innovate the products according to the actual situation of China's FRP market and broaden the application fields of the products. Our company has become one of the largest ,the most advanced equipment and most technical force professional manufacturers of Pultruded FRP structural profiles in North China.

FAQ

Q: Are you Manufacturer?

A:Yes. Our factories are located in Qingyun county , Dezhou city .

Our company was founded in 1993, introduced the world's most advanced FRP full-automatic pultrusion production equipment and inspection & testing equipment for products and materials from US .

Q: Do you supply the free sample ?

A: Yes. We supply the free sample what you are interested in .You only need to pay the freight for them.

Q:How about the Delivery time?

A: It depends on the quantity you order.

If you need customized products, we need more time to prepare mold for you .

There are more than 40 product lines in our factory .

Q:How about the FRP product ‘s service life?

A:The effective service life is 10-15 years. It will be longer if they are under normal working condition .

Q: How about Payment terms?

A: The payment terms are T/T, L/C at sight. Western Union, Paypal, Moneygram, Alipay, Credit card .